Not only vacuum filters capture dust and allergens, but the filtration captures minute or micron-sized particles. So, the filters are preventing the dust particles and allergens to settle in the air. In this modern age where technology has evolved big time, people are getting more concerned about their well-being and to keep their surroundings clean. Vacuuming is one of the safest practices to be used by the facility cleaners, the occupants of residential areas, and also various industrial usages.

There are five main types of industrial vacuum pumps:

- Diaphragm vacuum pumps

- Scroll vacuum pumps

- Liquid ring vacuum pumps

- Rotary vane vacuum pumps

- Turbomolecular vacuum pumps

The kind of pump you will buy depends on the type of vacuuming it requires hence, filtration also matters.

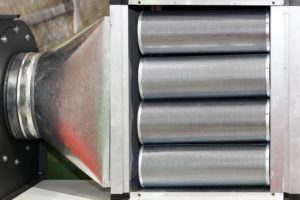

Features of Vacuum Filters

At times there can be confusion regarding the types of vacuum cleaner filters available. What some people call a type of vacuum cleaner filter is a feature that is found in the filters. Here is a list of some common features:

- Microfresh filters

- HEPA filters

- Wet/dry filters

- ULPPA filters

Choosing A Vacuum Filter Pump

There are several things to take into consideration when choosing a vacuum filter pump. Most importantly, your choice should align with the purpose you intend to use it for. This will allow you to determine the lubrication, technology, features, vacuum level, and the required flow rate.

The primary factor for choosing a filter pump is the quality and desired vacuuming level. There are different types of vacuum filters available which include low or rough vacuuming, high vacuuming, and ultra-high. What sets them apart is the way how molecules are vacuumed. Hence, it is of utmost importance to have a good-quality vacuum.

Also, consider the following characteristics such as:

Chemical Compatibility:

It is vital to consider the compatibility of the vapors and fumes used in your device when choosing a vacuum filter pump. Analyze all the aspects and know all the possible problems the appliance may encounter.

Pump Flow Rate:

The flow rate is determined by the draining time of the machine. It is important to evaluate the capacity of the vacuum as per the process requirements. Usually, it is believed that the higher the flow rates, the shorter the draining time.

Lubrication:

A lubricated pump provides better performance and efficiency. It does require regular maintenance and care hence it is important to know if lubricating the pump is required or not.

Maintenance and Cost:

It is important to analyze the frequency of the maintenance which will determine your overall costs. The installation process requires extra costs while the brand also matters.

The Primary Purpose of Vacuum Pumps

Vacuum filter pumps are used in many segments mainly industrial sectors, medical, laboratories, pharmaceutical industries, and mass spectrometry.

The vacuum pumps vary in terms of features and functionality. For instance, mass spectrometry will require having pressure between 10-3 and 10-4 mbars. Therefore, it is not necessary to use high-end technology that has an ultrahigh vacuum. If your area of segment is agri-food industry, drying, or distillation, then you will require buying a rough vacuum.

If you are involved in vacuum mixing or beam welding, experts suggest switching to a high vacuum. If, however, you work in particle acceleration, it is recommended using an ultrahigh vacuum.

In conclusion, there are several types of vacuum filters pumps, with each one having unique properties. When shopping for one, consider the environment where it will be used, the kind of work it will be doing, and overall maintenance and cost.